Quality Scaffolding Surrey for Both Residential and Commercial Projects

Quality Scaffolding Surrey for Both Residential and Commercial Projects

Blog Article

Discovering the Different Sorts Of Scaffolding Utilized in Building Jobs

The building and construction market relies greatly on numerous kinds of scaffolding to meet details task demands, each offering distinct benefits and applications. Typical framework scaffolding offers a durable foundation for general jobs, while put on hold scaffolding is essential for job on high-rise frameworks. Other options, such as system and rolling scaffolding, provide to efficiency and wheelchair, respectively. The cantilever alternative verifies invaluable in metropolitan environments where area is constricted. Comprehending the subtleties of these scaffolding kinds is crucial for maximizing safety and efficiency on building and construction websites, prompting a better evaluation of their unique features and applications.

Traditional Frame Scaffolding

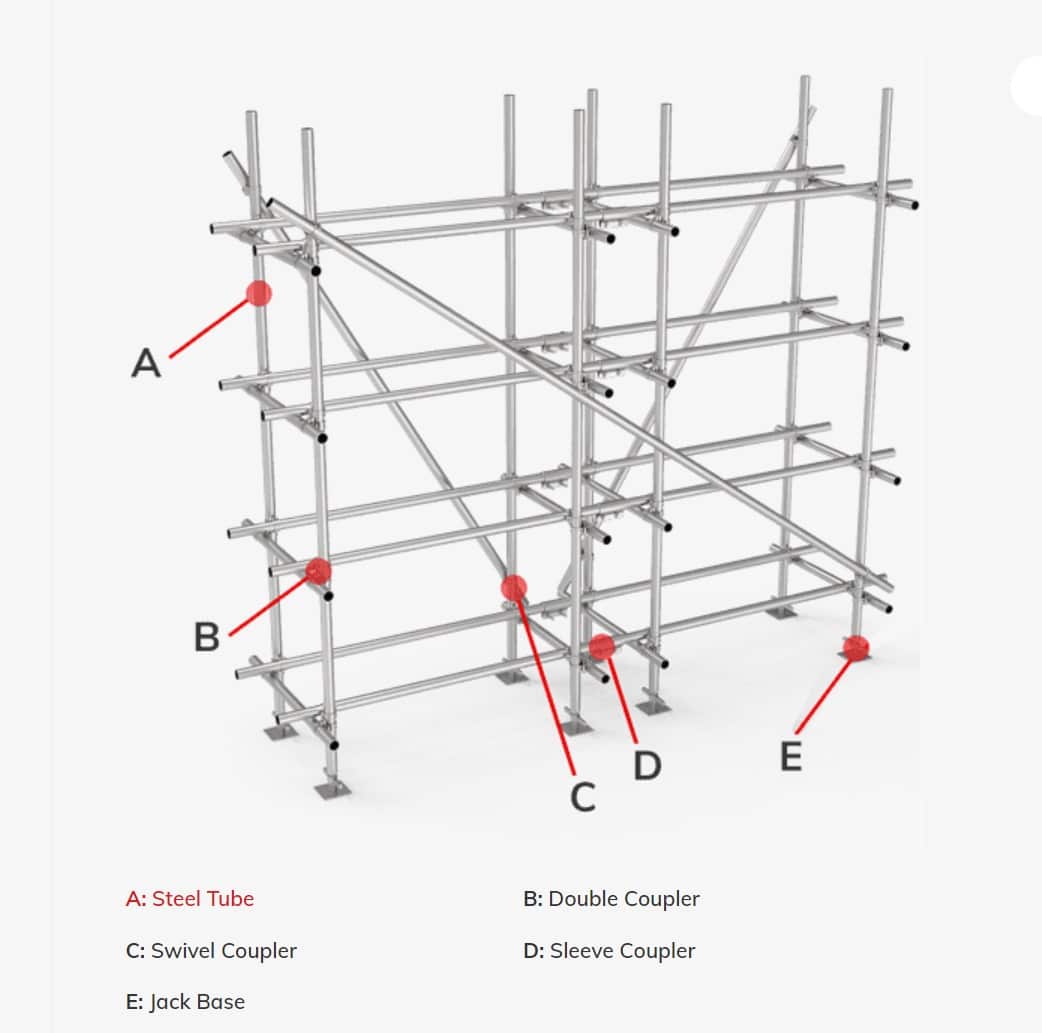

Traditional framework scaffolding is just one of the most widely used techniques in the construction sector because of its robustness and versatility. This system is composed of vertical and straight structures that are put together to develop a stable system for employees and materials. The major elements consist of upright articles, horizontal journals, and angled braces, which together offer a solid framework that can support substantial loads.

One of the crucial benefits of standard structure scaffolding is its adaptability to different building tasks, varying from domestic buildings to big commercial structures. The modular style permits very easy assembly and disassembly, making it efficient for both long-term and short-term jobs. Additionally, the system can be customized in height and width, accommodating various structure layouts and website conditions.

Security is critical in scaffolding applications, and standard framework systems are geared up with guardrails and toe boards to avoid drops and make sure employee security. Routine assessments and adherence to security policies are essential in keeping the honesty of the scaffold (Scaffolding). Overall, traditional structure scaffolding remains a basic option in the building market, providing a dependable platform for labor and boosting general job efficiency

Suspended Scaffolding

Put on hold scaffolding provides a special solution for building tasks that need access to elevated surface areas, specifically in circumstances where standard structure scaffolding may be unwise. This sort of scaffolding is normally put on hold from the roof or upper levels of a framework, utilizing a system of platforms, pulley-blocks, and ropes to create a working area that can be gotten used to various elevations.

One of the primary advantages of suspended scaffolding is its flexibility. It can be quickly rearranged or reduced to fit modifications in building demands, making it suitable for tasks such as window installation, façade job, and maintenance on high-rise buildings. Additionally, the very little impact of put on hold scaffolding enables far better usage of ground room in metropolitan settings, where room is usually limited.

Security is an essential factor to consider in using suspended scaffolding. Correct rigging and securing systems have to be used to ensure stability and stop mishaps. Operators should additionally be trained in the safe use this equipment. On the whole, put on hold scaffolding supplies a effective and efficient remedy for accessing hard-to-reach locations in numerous building scenarios, enhancing both performance and safety and security on site.

System Scaffolding

System scaffolding, typically concerned as a modern-day service in the scaffolding industry, includes pre-engineered parts that can be promptly constructed and adapted for various construction tasks. Scaffolding. This sort of scaffolding is identified by its modular style, which allows for convenience and effectiveness on work sites, accommodating different heights and architectural requirements

Usually made from high-strength steel or aluminum, system scaffolding supplies enhanced durability and stability. The parts include upright blog posts, horizontal journals, and diagonal dental braces, which adjoin safely, guaranteeing a robust structure. The layout typically includes standardized fittings, streamlining assembly and disassembly procedures, thereby decreasing labor time and expenses.

Rolling Scaffolding

Moving scaffolding is a versatile alternative to traditional set scaffolding, developed for movement and convenience of use on building sites. This kind of scaffolding consists of a system supported by structures with wheels, enabling employees to conveniently move it as required. The movement feature substantially enhances performance, as it reduces downtime associated with dismantling and putting together fixed scaffolding.

Normally constructed from light-weight materials such as aluminum or steel, rolling scaffolding offers a durable yet mobile solution for jobs needing regular repositioning - Scaffolding. It is particularly helpful in jobs such as paint, drywall setup, and electric job, where access to different heights and locations is required

Safety and security is paramount in rolling scaffolding design, with attributes such as locking wheels to avoid unexpected activity when in operation, and guardrails to safeguard employees from drops. Additionally, lots of versions are flexible anchor in height, suiting numerous task needs.

Cantilever Scaffolding

The style of cantilever scaffolding commonly includes making use of arms or braces anchored to a structure or structure, enabling the system to prolong outside securely. Safety is extremely important; therefore, these scaffolds need to be engineered to stand up to various tons and environmental scaffold netting screwfix conditions. Routine inspection and maintenance are important to make sure structural integrity and worker security.

Cantilever scaffolding is favored for its adaptability and effective usage of space, making it a prominent option in city atmospheres where area restraints prevail. It helps with much easier accessibility to high altitudes, ultimately contributing to the overall efficiency of building jobs. Similar to all scaffolding types, appropriate training and adherence to safety and security criteria are vital for employees utilizing cantilever scaffolding.

Final Thought

Finally, the varied kinds of scaffolding used in construction tasks each offer distinctive purposes tailored to certain website demands. Typical frame scaffolding offers stability, while suspended scaffolding provides adaptability for elevated jobs. System scaffolding promotes fast setting up, and rolling scaffolding enhances mobility for differing workplace. Cantilever scaffolding effectively addresses obstacles in urban setups. Understanding these check it out scaffolding kinds is vital for optimizing safety and security and efficiency in building, eventually adding to the successful conclusion of projects.

Traditional structure scaffolding supplies a strong foundation for basic tasks, while put on hold scaffolding is essential for job on high-rise frameworks.Rolling scaffolding is a functional choice to traditional fixed scaffolding, made for wheelchair and ease of use on building websites. As with all scaffolding kinds, proper training and adherence to safety and security requirements are vital for workers using cantilever scaffolding.

Traditional framework scaffolding offers security, while suspended scaffolding provides flexibility for raised jobs. System scaffolding helps with fast assembly, and rolling scaffolding enhances flexibility for varying job settings.

Report this page